1996

Establishment of a quality management system according to DIN EN ISO 9001, VDA 6.1 and QS-9000.

Equipped with state-of-the-art measuring and testing facilities, our technical center makes it possible for engineers to offer feasible solutions at short notice.

All new testing machines consist of software-controlled digital measuring systems that fully meet the requirements of the automotive industry. Even new product ideas can quickly be brought into series production.

We also have two special machines that enable us to fulfill specific tasks. These are a 1000-Hz test machine to inspect even high-frequency acoustic phenomena and a mobile measurement system with 16 channels to record and evaluate a wide range of measured variables directly in the vehicle.

We use the test rig for analyzing spray mist reduction systems to check the efficiency of existing and new systems under largely realistic conditions (axle loads up to 60 kN and speeds up to 80 km/h).

Establishment of a quality management system according to DIN EN ISO 9001, VDA 6.1 and QS-9000.

First certification according to ISO 9001, VDA 6.1 and QS-9000 (requirement by the German and American automotive industry).

First certification of the quality management system according to the globally applicable ISO/TS 16949:1999.

Establishment of an integrated management system (quality and environment).

Upgrade level based on DIN EN ISO 9001:2000 and ISO/TS 16949:2002. First certification of the environmental management system according to DIN EN ISO 14001.

Modification of the environmental management system according to DIN EN ISO 14001:2005.

Establishment and certification of an energy management system according to DIN EN ISO 50001:2011.

Modification of the integrated management system according to IATF 16949:2016 and DIN EN ISO 14001:2015.

Certification according to the new IATF 16949:2016 and re-certification according to DIN EN ISO 14001:2015.

Modification and certification of the energy management system according to DIN EN ISO 50001:2018.

In addition to a test rig for spray mist reduction systems, we use the following other testing machines:

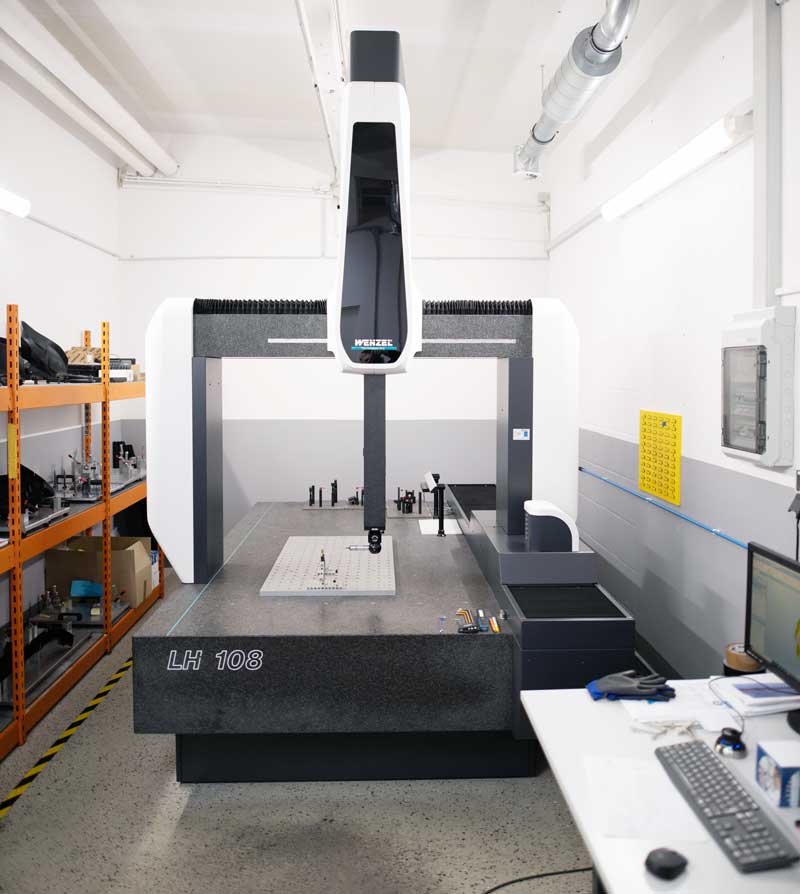

In a measuring volume of 1600 x 1000 x 800 mm, our 3D coordinate measuring machine from the Wenzel company enables us to perform high-precision, production- and process-associated tactile measuring tasks with a limit value of the length measurement deviation of “E01 MPE = 1.7 µm + (L/350 mm) µm”.

With our regular maintenance and calibration by DAkkS (German Accreditation Body), we fully comply with the requirements of the IATF 16949 standard of the automotive industry.

Modular clamping devices and component-specific measurement recordings, in conjunction with measurements against CAD data and CAD models, enable us to act quickly and flexibly.

Your specialist for plastic products and molded rubber parts specialized for the automotive industry.

WEGU Holding GmbH

PO box 31 04 20

34123 Kassel

info@wegu.de

+49-561-5203-0